Quality

The prime evidence of Renuka do Brasil's quality is the level of the clients who they traditionally serve. Among them, are the principal international sugar trading companies and the largest national distributors of fuel and electric energy.

To meet the highest expectations, the sales staff is integrated with the areas of production and logistics to conform in detail with the client all aspects related to product specifications and delivery methods.

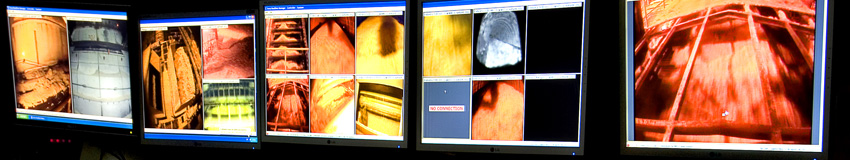

The consistency of characteristics of sugar, ethanol, and yeast is guaranteed by an experienced operational staff and a quality corps, highly conscientious and supported by modern methodologies and laboratories. Some of the equipment most used are: Anton Paar densimeters, Schmidt+Haensch polarimeters, Atago refractometers, Hach spectrophotometers, Foss Near infrared spectrophometers (NIRS), Leco protein analyzers, HP gas chromatographs, Perkin Elmer Plasma mass spectrometers, among others.

Mill Madhu was the first sugar/ethanol unit to obtain ISO 9001 in all its processes in 1996. Also, since 2003 it has certification GMP B2 (Quality Control of Feed Materials) in the yeast fabrication process.